An analysis of the advantages and disadvantages of variable frequency water supply and non-negative pressure water supply from deep wells in the factory area and an introduction to the principle of constant pressure variable frequency and non-negative pressure water supply.

Abstract

Traditional factories and large-volume water supply use secondary pressurization, build water towers, and install water tanks on high floors to meet the water supply pressure requirements of all aspects of the factory. However, there are problems of energy waste and secondary pollution of water sources. With the development of science and technology, the application of variable frequency water supply can save energy to a certain extent, but the water source still has the problem of secondary pollution. The non-negative pressure water supply method can solve the above problems and has the functions of energy saving, water saving and no secondary pollution.

Common water supply methods

- Water supply from water tower – The “oldest” high-rise water supply method is water tower water supply. Deep well water is transported to the water tower through a deep water pump, and finally the water is supplied through the pressure difference formed between the water tower and the building. It is a gravity water supply method. The disadvantage is that the water tower occupies The land area is large, the construction cost is high, and secondary pollution is serious. As urban buildings become taller and taller, the height of water towers can no longer meet current needs and are destined to be eliminated.

- Water supply from water tank – The water supply of water tanks and reservoirs is to transport the water from deep wells to reservoirs or water tanks through water pumps. The water supply of water tanks is divided into two stages. The first stage is to use the method of “water well + water pump + reservoir or water tank”. The water is pressurized into the storage tank, and then pressurized by a fixed-speed pump before being sent to the user. The water tank plays a role in regulating high and low peak water usage. The second stage adopts the method of “storage tank + variable frequency speed regulating water pump”. After setting the water supply pressure of the water pump, under the control of the frequency converter, the speed of the water pump changes with the change of water volume. The result of reducing the speed is to reduce the The reduced power reduces energy consumption to a certain extent.

- Non-negative pressure water supply – The non-negative pressure water supply directly utilizes the residual pressure of the deep water pump, and directly superimposes the water supply on the basis of the deep water pump pressure. When the deep water pump is pumped to the water inlet of the water pump, the residual pressure can be superimposed to utilize the head. The water pump only supplements the insufficient part of the set water pressure and residual pressure, and the energy saving effect is obvious.

Frequency Conversion Constant Pressure Water Supply

- Working principle – The water supply pressure value is set for the water pump in advance. The pressure sensor detects the pressure of the pipe network and feeds the signal back to the controller or microcomputer controller. After analysis and processing, the signal is transmitted to the frequency converter to control the operation of the water pump. When the water consumption increases, the output voltage and frequency increase, the water pump speed increases, and the water output increases; when the water volume decreases, the water pump speed decreases, reducing the water output, so that the pipe network pressure maintains the set pressure value. When multiple water pumps are running, each water pump is soft-started one by one, and the variable frequency is converted to the mains frequency until the pressure and flow rate are satisfied, thereby realizing the cyclic control of the water pumps. However, when running at low flow rate at night, the variable frequency water pump can be used to maintain operation, and the variable frequency water supply pump can be shut down to maintain pressure.

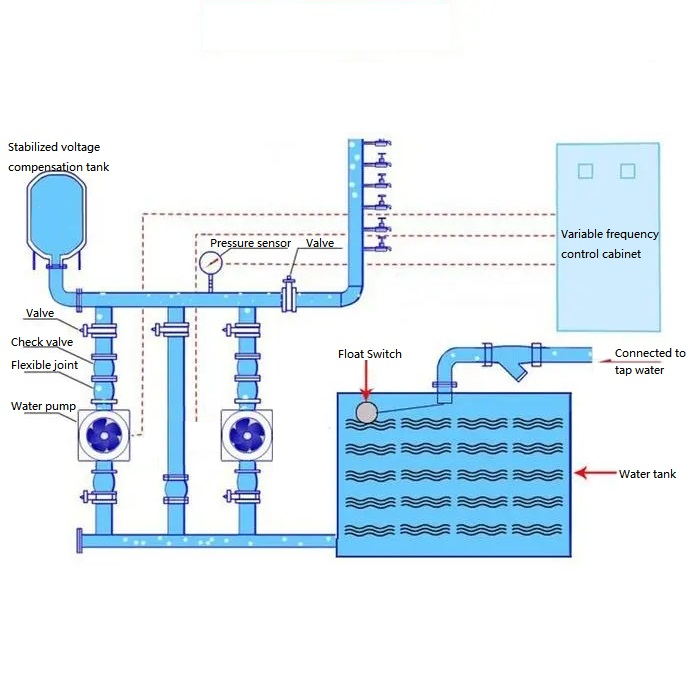

- Composition of variable frequency water supply control system – The automatic monitoring system includes real-time monitoring of water volume in the reservoir and water pressure in the pipe network. Pipe network water pressure monitoring: Install a pressure sensor on the main pipe of the water supply system. The pressure sensor converts the collected data into an electrical signal and transmits it to the frequency converter. The frequency converter changes the output power through corresponding logical operations, thereby adjusting the speed of the frequency conversion pump. Finally, Keep the water pressure of the variable frequency pump in balance with the user’s water pressure. Water volume monitoring in the reservoir: Install a float level sensor in the reservoir to monitor the water volume in the reservoir. When the water volume in the pool is too low, the detection system will feedback the current situation to the control system, and the water supply system will implement automatic protection.

(1) Frequency conversion pump unit – It is composed of an electric motor unit and multiple water pumps. When the water consumption does not change much, the system will be operated by a water pump with frequency conversion and speed regulation according to the quantity change. When water consumption increases, pressure within the piping system decreases. When the water volume is greater than the water output of one pump, the first pump switches to power frequency operation, and the second pump starts variable frequency speed regulation operation. When the water consumption is less than the water output of the two pumps, it can automatically stop the operation of one or two pumps. During the entire operation, the constant pressure of the system is always maintained.

(2) Automatic control system – The main function is to automatically adjust the frequency of the frequency converter according to the water pressure of the pipe network and the water consumption in the factory, thereby adjusting the running speed of the water pump and ultimately ensuring constant pressure water supply. It generally includes frequency converters, PLCs and electronic control equipment.

(3) Computer monitoring system – It is used to display and control the operating status of all systems. Workers can use this system to grasp the operation of the entire water supply system. The water pressure preset value and control method can be modified conveniently and quickly according to the system, and the control system can also be started and stopped flexibly.

Non-Negative Pressure Water Supply

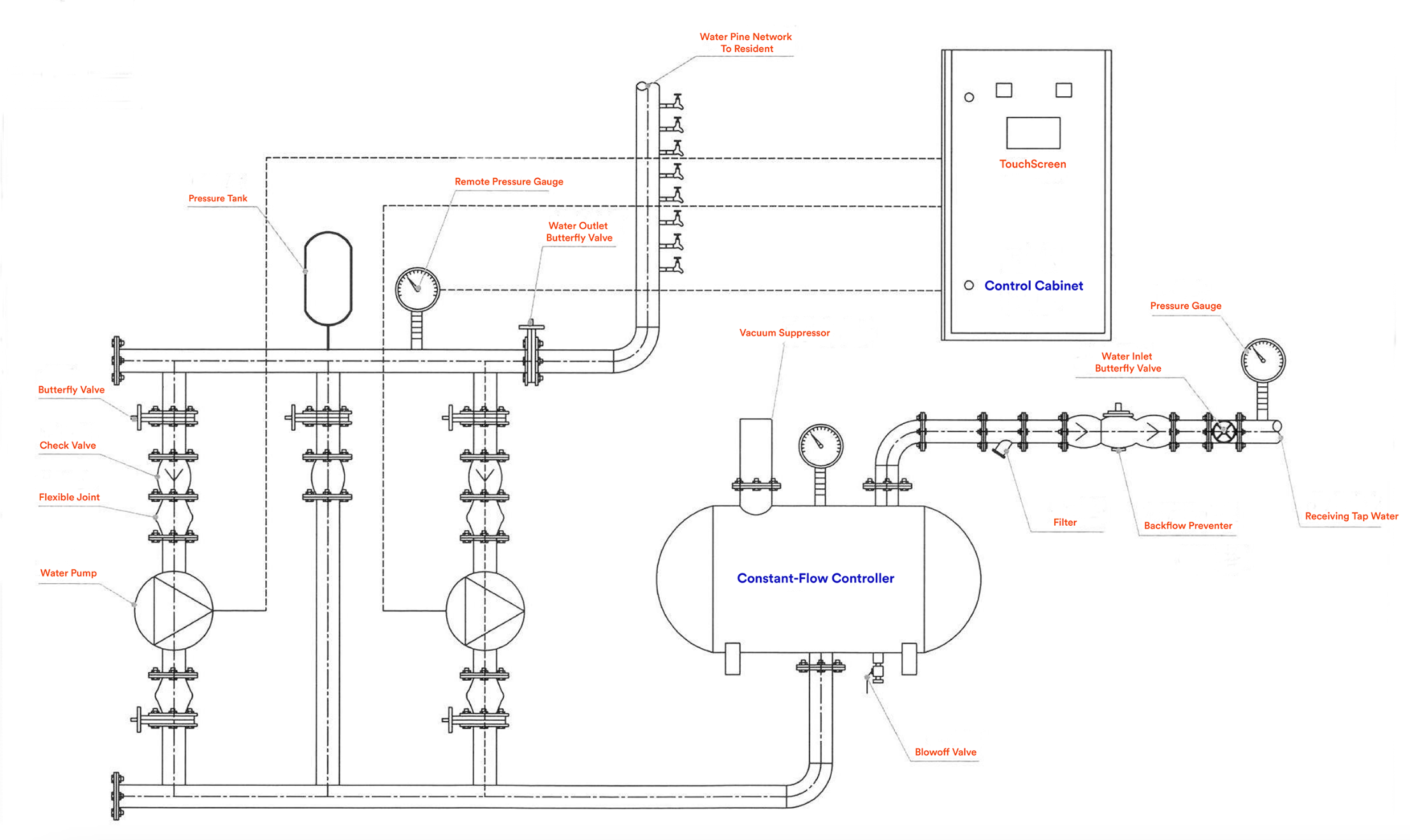

- System composition – Non-negative pressure water supply mainly consists of non-negative pressure steady flow tank, pressure tank (diaphragm type or air bag type expansion tank), non-negative pressure control cabinet, water pump, motor, negative pressure eliminator, filter, backflow preventer, sensor, electric It consists of contact pressure gauge, pipeline components, base, etc. The flow stabilizer is a device connected between the municipal pipe network and the water pump. Its main function is to eliminate the influence of negative pressure and stabilize and regulate the water flow.

- No negative pressure technology – The non-negative pressure water supply system adopts microcomputer frequency conversion technology and effective negative pressure processing technology to achieve overlapping pressure water supply. The equipment collects the vacuum degree and water level signals in the steady flow compensator through the monitoring devices in the pipe network pressure gauge, vacuum suppressor and steady flow compensator, provides real-time feedback, and controls the special parameters in the vacuum suppressor and steady flow compensator through the microcomputer. The device operates to suppress the generation of negative pressure and ensure that the equipment does not affect the deep water pump.

The system will not create negative pressure on the deep water pump. When the water pressure of the deep water pump decreases or even stops, the water pump unit can still work until the change in the water inlet and outlet time in the steady flow compensator appears negative or when the water pressure drops to the lower limit pressure set by the electric contact pressure gauge, The equipment can be controlled in a simple way to automatically shut down and start automatically after water comes in. During a power outage, the water pump unit stops working. When a call comes in, the unit automatically turns on and resumes normal water supply.

Advantages and Disadvantages of Variable Frequency Constant Pressure Water Supply And Non-Negative Pressure Water Supply

Advantages and disadvantages of variable frequency water supply

- Advantages – Compared with traditional water tower water supply, the basic construction is simple, the system form only requires a small water room (several water pumps, a control cabinet) and takes up a small area. The reliability of the equipment is high, the service life is long, and it can meet the needs of high-rise buildings. There is a water tank to store water, which can cope with short-term continuous water supply when the municipal pipe network is out of water.

- Disadvantages – External network water pressure cannot be used, water energy consumption is large, and installation, cleaning and maintenance are troublesome. Since it is still a secondary water supply, there are still water pollution problems. In severe cases, red worms will appear. When the equipment is running, there will be disturbances such as vibration of the water pump and loud noise.

Advantages and disadvantages of water supply without negative pressure

- Advantages – Making full use of the municipal pipe network pressure can greatly save energy. The system operates in a fully sealed manner to avoid secondary pollution of water. There is no need to build a reservoir, saving floor space and investment. There is a complete set of non-negative pressure equipment on the market that only needs to connect the inlet and outlet pipes. It is simple to install and easy to manage and maintain. Save operating costs and maintain constant pressure. When the equipment has a power outage, water can be supplied from the municipal pipe network, and the underlying building can still receive continuous water supply.

- Disadvantages – Non-negative pressure water supply has certain disadvantages, because there is no water tank in non-negative pressure water supply. Once the municipal pipe network shuts down water, users will soon be without water.

Introduction to Variable Frequency Constant Pressure Water Supply Equipment:

The variable frequency constant pressure water supply system refers to a water supply method in which the outlet pressure remains unchanged when the water consumption in the water supply pipe network changes. The outlet pressure value of the water supply pipe network is determined based on user needs. The traditional constant pressure water supply method is achieved by using water towers, high water tanks, pressure tanks and other facilities.

- Operating principle – According to the equipment requirements, first set the water supply pressure value, and then power on the operation. The pressure sensor monitors the pipe network pressure and converts it into an electrical signal and sends it to the programmable controller or microcomputer controller. After analysis and processing, the signal is transmitted to the frequency converter for control. When the water pump is running, when the water consumption increases, its output voltage and frequency increase, the pump revolutions increase, and the water output increases. When the water volume decreases, the water pump revolutions decrease, reducing the water output, so that the pipe network pressure maintains the set pressure. value, when multiple pumps are running, each machine is soft-started, and the variable frequency is converted to industrial frequency until the pressure and flow rate are satisfied, realizing the cyclic control of the water pump. When the small flow rate is running at night, the variable frequency water pump can be used to maintain the work. The variable frequency water pump Can be shut down to maintain pressure.

- Equipment composition – The variable frequency constant pressure water supply equipment is mainly composed of a water pump unit, a pressure measuring and stabilizing tank, a pressure sensor, a variable frequency control cabinet, etc. It can always maintain the pressure gauge pressure (The user’s pipe network water pressure) equal to the user’s set value. It can be used for general domestic or production water supply.

The water supply system consists of

- The frequency conversion water supply equipment is connected to the factory’s deep water well to provide constant pressure water supply. When the water supply pressure can meet the needs, all water pumps will automatically stop operating. Otherwise, the constant pressure water supply equipment starts to increase the pressure to meet the water requirements.

- Attach a small pump or pressure tank. In order to completely eliminate the power consumption of low-flow or zero-flow water supply, an auxiliary small pump or auxiliary pressure tank can be added. When the water supply pressure is low, the main pump will be automatically stopped to allow the small pump or pressure tank to operate.

Features

- Using programmable controller, the program is flexible and changeable, with high precision, strong reliability, multiple functions and fast response speed.

- They are all equipped with a voltage stabilizing pump or a voltage stabilizing tank. When the water consumption reaches a certain value, the main pump can stop running, reducing mechanical wear of the water pump motor and saving electricity.

- All water pumps are soft-started to extend the life of the equipment and eliminate the impact of the starting current on the power grid.

- According to the change of water consumption, the water pump runs in a cyclic frequency conversion, starting first and stopping first, so that the water pump works in a balanced manner. When one pump runs for six hours or twenty-four hours, it automatically switches to the other one.

- The biggest feature is dual constant voltage control, which can be used as a common set of equipment for domestic fire protection, saving investment for users. Moreover, one machine can be used for two purposes, which greatly improves the efficiency of use.

- Compact structure, small footprint, fast installation, low investment and stable operation. No pollution.

Application scope

- Domestic water for residents.

- High-rise buildings, residential areas, villas.

- Production and domestic water use in industrial and mining enterprises.

- Fire protection projects, garden irrigation, hotels, office buildings and other forms of water supply transformation.

Introduction To The Principle Of Non-Negative Pressure Water Supply Equipment

The non-negative pressure water supply equipment is a pressurized water supply unit directly connected to the deep well pump in the factory. Based on the residual pressure of the deep well pump, the water supply is superimposed in series to ensure that the pressure of the factory pipe network is not less than the set protection pressure (which can be 0 pressure relative to the pressure), when the pressure is less than 0, it is called negative pressure) secondary pressurized water supply equipment. The core of the pipe network superimposed (no negative pressure) water supply equipment is how to prevent the generation of negative pressure during the operation of the secondary pressurized water supply system, eliminate the impact of unit operation on the deep water pump, and achieve safety without affecting other water uses, reliable, stable and continuous water supply. Non-negative pressure water supply equipment is also called pipe network overlapping water supply equipment. Currently, there are mainly tank-type non-negative pressure water supply equipment and box-type non-negative pressure water supply equipment on the market. The water inlet pipe of the negative pressure water supply equipment is directly connected to the tap water pipe network. Water is forced into the equipment inlet pipe driven by the residual pressure of the deep water pump. The pressurized water pump of the equipment continues to pressurize based on the residual pressure of the inlet water, increasing the water supply pressure to the user After the required pressure is reached, water is supplied to the outlet pipe network; when the water consumption of the equipment is greater than the water supply of the deep water pump, the pressure of the water inlet pipe network drops. When the pressure at the water inlet of the equipment drops to an absolute pressure less than 0 (or the set pipe network protection pressure) When , the negative pressure prevention and control device in the equipment automatically starts working, and the operating status of the equipment is adjusted until the equipment is shut down and on standby to ensure that the pressure of the water inlet pipe network will no longer decrease and adversely affect the deep water pump; when the water supply capacity of the deep water pump is restored, When the pressure of the water inlet pipe network returns to above the protection pressure, the equipment automatically starts and resumes normal water supply; when the remaining pressure of the deep water pump meets the water supply requirements of the equipment, the equipment automatically enters a dormant state, and the deep water pump directly supplies water to the user. When the water supply is insufficient, the equipment automatically Resume operation; when the user does not use water or the water consumption is very small, the equipment automatically enters the shutdown and dormant state. The small flow pressure stabilizing and holding tank located on the water outlet side of the equipment maintains the small amount of water used by the equipment and the leakage of the pipe network. The equipment water pressure stabilizing and holding tank When the required pressure of the water supply network cannot be maintained, the device automatically wakes up and resumes normal operation. During the operation of the equipment, the remaining pressure of the deep water pump is fully utilized, which always meets the needs of the equipment to the maximum extent without adversely affecting the deep water pump, reduces water supply energy consumption, and achieves optimal operation of the water supply system.

Working principle:

- No negative pressure flow controller – A non-negative pressure controller is used to monitor and control the pressure in the deep water pump and compensation tank at all times. When the pressure of the deep water pump is insufficient, the non-negative pressure controller starts to work to ensure that the water pressure of the deep water well is not affected. Document No. 135 of the Water Supply Company stipulates that municipal The pressure cannot be lower than 2KG. The non-negative pressure flow controller not only ensures the safety and stability of the water used in the equipment, but also ensures the stability of the deep water pump pressure.

- Two-way compensation device – The energy storage and release adjustment device is used for bidirectional compensation, which can automatically compensate for the continuous water volume of the deep water pump. It can also play a role in stabilizing and compensating the equipment pipe network to ensure that the equipment does not produce negative pressure for the deep water pump. Low-peak water supply bidirectional compensator Working, the high-pressure water at the outlet end of the water pump is directed to the low-pressure chamber to replenish water to the low-pressure chamber. After the low-pressure chamber is filled, it is closed and then continues to replenish water to the high-pressure chamber. When the liquid level gradually rises, the pressurized inert gas is squeezed back into the energy storage device. In this way, the process of replenishing water in the tank during the low peak period is completed. When the water supply or deep water pump pressure drops during the peak period, the two-way compensation device replenishes water from the low pressure chamber to the constant pressure chamber. At the same time, the energy storage device releases energy and accumulates water. The water in the high-pressure chamber is replenished to the low-pressure chamber, and the deep water pump in the constant-pressure chamber is used to replenish water. This completes the process of replenishing water to users during peak periods.

- Energy storage – It uses an energy storage device with built-in inert gas that is under pressure and does not float in water. When water is supplied during peak periods, energy is released to squeeze the high-pressure chamber water to replenish water at low pressure. It makes full use of the principle of energy conservation law to replenish water to the equipment during peak periods and ensure that the tank The water in the system can be compensated to the equipment pipe network to the greatest extent, suppressing the generation of negative pressure and ensuring that it does not affect the city’s deep water pump.

Conclusion

This article briefly analyzes the principles, advantages and disadvantages of variable frequency water supply and non-negative pressure water supply. Generally speaking, non-negative pressure water supply is the continuation and development of variable frequency water supply. It has the advantages of low investment, high degree of automation, and energy saving. Sub-pollution and other characteristics are worthy of promotion and application. However, considering the actual conditions of the plant, a water storage tank needs to be installed (to avoid frequent starting of the deep water pump).