In today’s world, where high-rise buildings dominate cityscapes and industrial processes demand high fluid pressure, booster pump systems play a crucial role. These systems ensure that water and other fluids reach their intended destinations with adequate pressure and flow. In this article, we will delve deep into the workings, types, and applications of booster pump systems, providing you with a comprehensive understanding of this essential technology.

What is a Water Booster Pump?

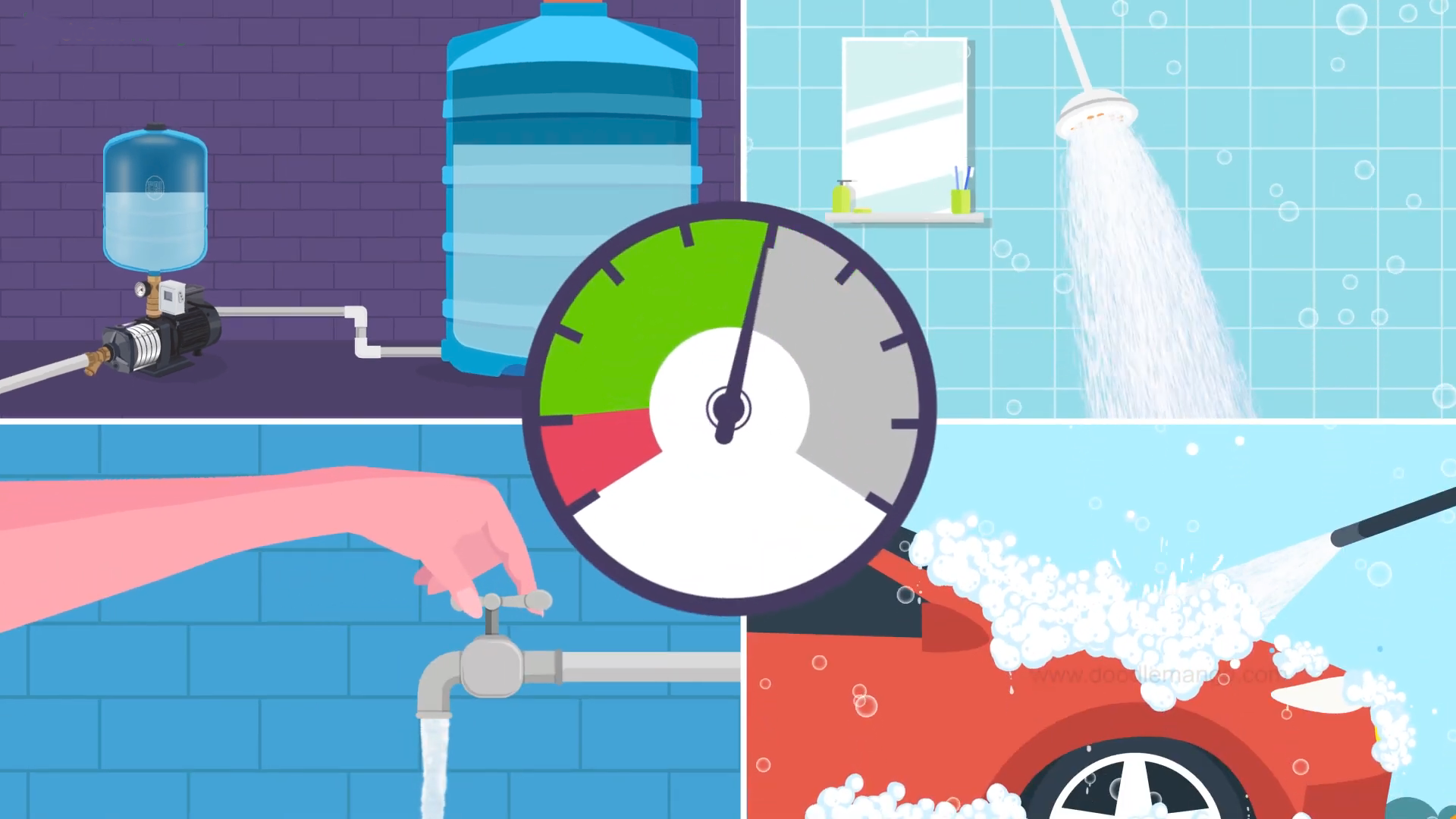

A water booster pump is a device that enhances water pressure and flow in various settings, from residential homes to commercial buildings and industrial facilities. Here’s a quick rundown:

What Does a Water Booster Pump Do?

- Increases Pressure: It boosts water pressure in systems where the existing pressure is insufficient.

- Improves Flow: Ensures consistent and adequate water flow to all fixtures and outlets.

How It Works?

- Intake: The pump draws water from a source.

- Boost: The pump, powered by a motor, increases the pressure.

- Delivery: The pressurized water is then pushed through the system, providing stronger flow at the outlets.

What is a Booster Pump System?

A booster pump system is designed to increase the pressure of a fluid, whether it be water, gas, or any other liquid. These systems are particularly vital in scenarios where the existing pressure is insufficient to meet the requirements of the application.

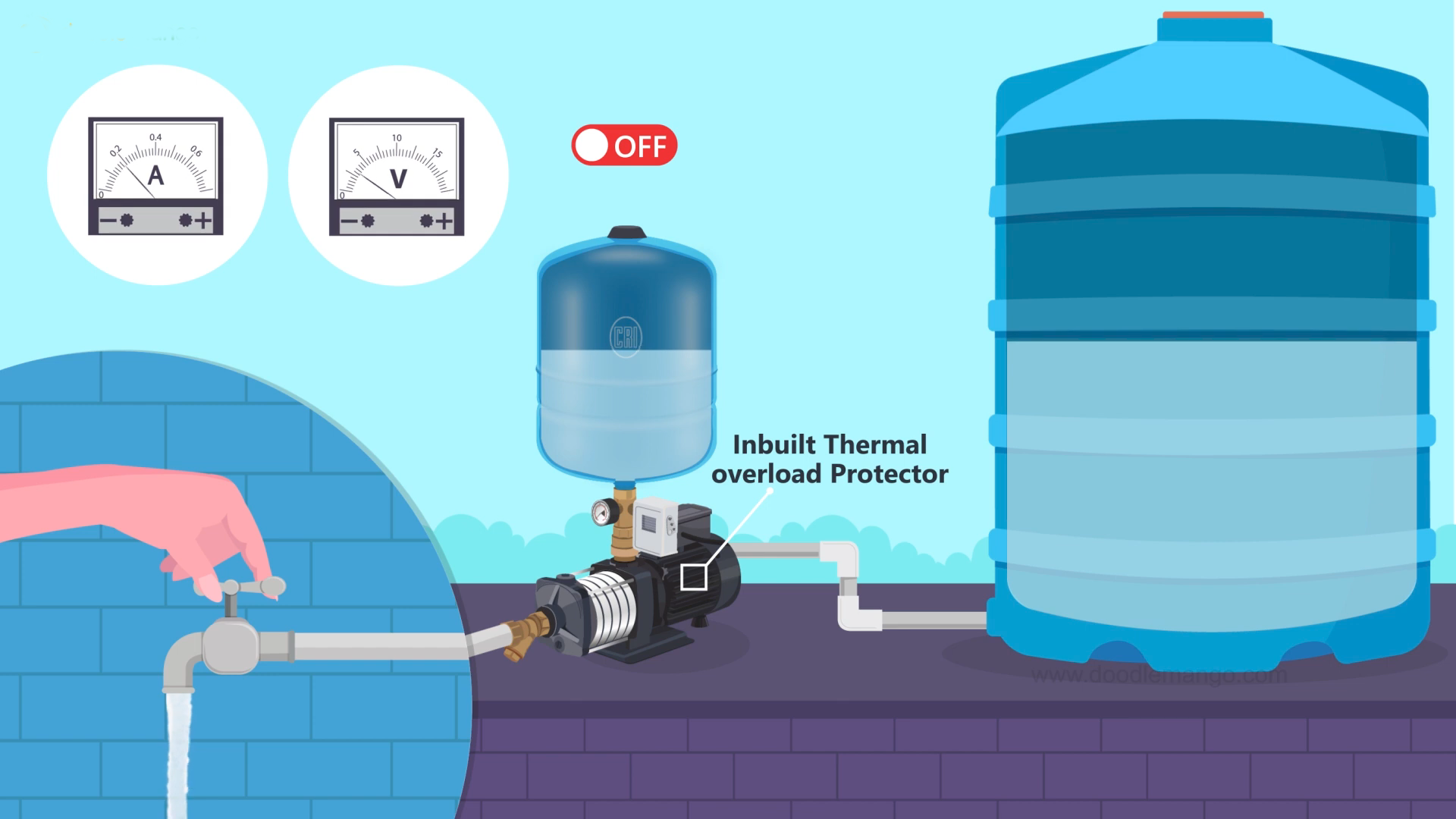

Key Components of Booster Pump System:

- Pump: The main device that boosts water pressure.

- Motor: Drives the pump, usually powered electrically.

- Pressure Switch: Monitors pressure levels and turns the pump on/off automatically.

- Control Panel: Manages the operation of the pump, often including features like alarms and performance monitoring.

- Check Valves: Prevents backflow of water into the pump.

- Pressure Tank (Optional): Helps maintain consistent water pressure and reduces pump cycling.

How Does a Booster Pump System Work?

The fundamental principle behind a booster pump system is to take in fluid at a lower pressure and discharge it at a higher pressure. Most booster pumps operate using centrifugal force, where an impeller rotates to increase the pressure and flow of the fluid. The process involves the following steps:

- Intake: Fluid enters the pump through an inlet.

- Pressurization: The impeller, driven by a motor, rotates, creating centrifugal force that increases the fluid’s pressure.

- Discharge: The pressurized fluid exits the pump through an outlet, ready to be delivered to its destination.

Types of Booster Pump Systems:

1. Single-Stage Booster Pumps

Single-stage booster pumps are equipped with a single impeller that increases the fluid pressure. These pumps are suitable for applications with moderate pressure requirements, such as residential buildings and small commercial establishments.

2. Multi-Stage Booster Pumps

Multi-stage booster pumps have multiple impellers arranged in series, allowing them to achieve higher pressure levels. These pumps are ideal for applications requiring significant pressure boosts, such as high-rise buildings, large commercial complexes, and industrial processes.

3. Variable Speed Drive (VSD) Booster Pumps

VSD booster pumps can adjust their speed based on the required pressure levels. This feature makes them energy-efficient and suitable for applications with varying pressure demands. VSD pumps are commonly used in HVAC systems, irrigation, and water treatment plants.

Applications of Booster Pump Systems:

Booster pump systems are versatile and find applications across various sectors:

1. Residential Buildings

In high-rise residential buildings, water pressure can diminish as it travels to upper floors. Booster pumps ensure that all residents receive adequate water pressure for their daily needs, including showers, faucets, and appliances.

2. Commercial Complexes

Commercial establishments, such as hotels, shopping malls, and office buildings, require consistent water pressure for various operations. Booster pumps maintain the necessary pressure levels, ensuring smooth functioning.

3. Industrial Processes

Industries often require high-pressure fluids for processes like filtration, reverse osmosis, HVAC, and boiler feed. Booster pumps play a crucial role in maintaining the required pressure levels for these processes.

4. Industrial Processes

Agricultural and landscaping irrigation systems need consistent water pressure to ensure even distribution of water. Booster pumps help achieve this, promoting healthy plant growth and efficient water usage.

5. Fire Protection Systems

Fire sprinkler systems in multi-story buildings rely on booster pumps to deliver sufficient water pressure to upper floors during emergencies. These pumps are often powered by diesel engines or large electrical motors with battery backups to ensure reliability.

Choosing the Right Booster Pump System

Selecting the appropriate booster pump system depends on several factors, including the required pressure, flow rate, and application. Here are some key considerations:

1. Pressure Requirements

Determine the pressure level needed for your application. Single-stage pumps are suitable for moderate pressure needs, while multi-stage pumps are ideal for high-pressure applications.

2. Flow Rate

Calculate the flow rate required to meet your demands. Consider all fixtures and appliances that will use the booster pump to ensure it can handle peak flow rates.

3. Source and Destination

Consider the location of the water source and the destination. If the water needs to be pumped uphill or to higher floors, a more powerful booster pump may be necessary.

4. Energy Efficiency

Variable speed drive (VSD) pumps are energy-efficient and can adjust their speed based on pressure requirements. They are a good choice for applications with varying pressure demands.

5. Maintenance

Consider the maintenance requirements of the booster pump system. Some pumps may require regular servicing and parts replacement to ensure optimal performance.

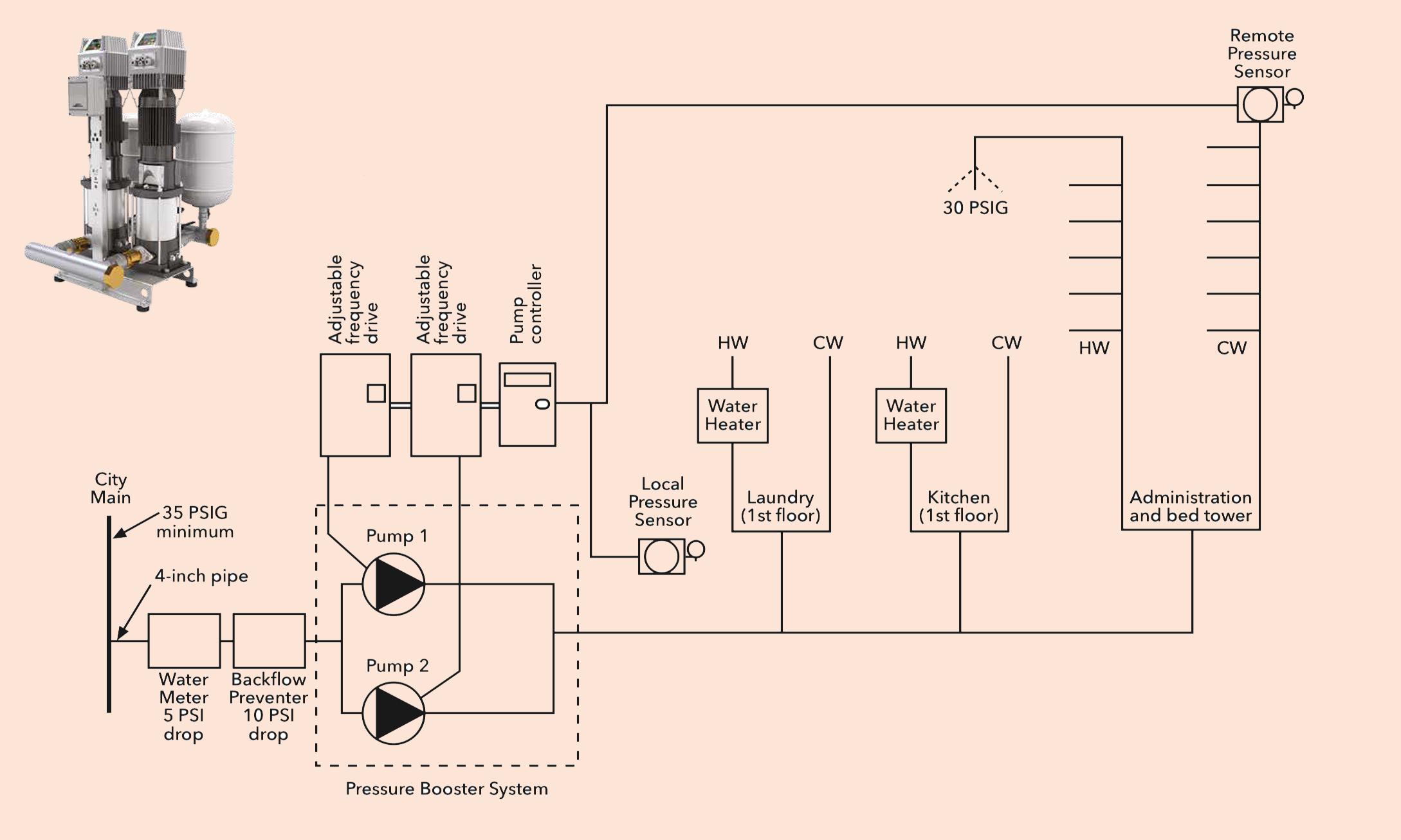

Booster Pump System Design

Here’s a step-by-step guide to designing an effective booster pump system:

1. Understand System Requirements

A. Determine Flow Rate:

- Calculate the total flow rate needed, typically measured in gallons per minute (GPM) or liters per second (L/s).

- Consider peak demand scenarios (e.g., simultaneous water usage).

B. Pressure Requirements:

Determine the required boost in pressure, measured in psi (pounds per square inch) or meters of head.

Calculate this based on the following:

- Height to be lifted (static head).

- Pressure required at the outlet.

- Losses due to friction in pipes, fittings, and valves.

C. Fluid Properties:

Assess fluid characteristics like temperature, viscosity, and corrosiveness to select appropriate materials.

2. Select the Pump Type

- Centrifugal Pump: Ideal for high flow, moderate pressure systems.

- Multistage Pump: Suitable for high-pressure applications.

- Vertical Pump: Space-saving designs for high-rise applications.

- Submersible Pump: For underground tanks or reservoirs.

3. Include Necessary Components

A. Core Components:

- Pump: Sized based on the flow and pressure requirements.

- Motor: Matches the pump’s power needs (kW or HP).

B. Control Components:

- Pressure Switches: Automatically turn the pump on/off based on system pressure.

- Variable Frequency Drive (VFD): Modulates pump speed to match demand, saving energy.

- Control Panel: Manages system operation and integrates safety alarms.

C. Hydraulic Components:

- Pressure Tank: Reduces pump cycling and maintains consistent pressure.

- Check Valve: Prevents backflow and protects the pump.

- Strainers/Filters: Protect the pump from debris.

4. Optimize Piping and Layout

A. Pipe Sizing:

- Ensure proper pipe diameter to minimize friction losses.

- Use materials compatible with the fluid and pressure rating.

B. Pump Placement:

- Install close to the water source to minimize suction lift.

- Ensure a firm and level foundation to reduce vibration.

C. Bypass Line:

- Include a bypass line for maintenance without interrupting the water supply.

5. Consider Energy Efficiency

- Use pumps with high-efficiency motors.

- Incorporate energy recovery systems if applicable.

- Optimize operation through pressure modulation and real-time monitoring.

6. Safety and Monitoring

- Include sensors for pressure, flow, and temperature to detect abnormalities.

- Install relief valves to handle overpressure situations.

- Use remote monitoring systems for automated alerts and diagnostics.

7. Perform Calculations

Ensure your design meets the operational parameters:

- Hydraulic Calculations: Verify the pump can deliver the required flow at the desired pressure.

- Power Calculations: Ensure the motor has sufficient power (P = Q × H × ρ / efficiency).

8. Test and Validate

- Perform a hydraulic performance test after installation.

- Validate pressure levels and flow rates under varying loads.

Installation and Maintenance of Booster Pump Systems

1. Installation

Proper installation of a booster pump system is crucial for its efficient operation. Here are some steps to ensure a successful installation:

- Location: Install the pump close to the water source to minimize pressure loss.

- Bypass: Include a bypass system to allow water flow in case the pump fails.

- Testing: Test the pump before connecting it to the main system to check for leaks and proper operation.

- Vibration Control: Use flexible connectors to minimize noise and vibration.

2. Maintenance

Regular maintenance is essential to keep the booster pump system running smoothly. Here are some maintenance tips:

- Inspection: Regularly inspect the pump and its components for signs of wear and tear.

- Cleaning: Keep the pump and its surroundings clean to prevent debris from entering the system.

- Lubrication: Ensure that moving parts are properly lubricated to reduce friction and wear.

- Testing: Periodically test the pump to ensure it is operating at the desired pressure and flow rate.

Conclusion

Booster pump systems are indispensable in ensuring adequate fluid pressure and flow in various applications. From residential buildings to industrial processes, these systems play a vital role in maintaining efficient operations. By understanding the types, applications, and maintenance of booster pump systems, you can make informed decisions to meet your specific needs. Whether you need to boost water pressure in a high-rise building or ensure consistent flow in an industrial process, a well-chosen booster pump system can make all the difference.

If you have any questions or need assistance in selecting the right booster pump system, feel free to reach out to our team of experts. We are here to help you find the perfect solution for your fluid pressure and flow rate requirements.